Minerals, metals are characterized by complexity of plants, environmental concerns, siloed activities, and demands of sustainability.

The future of mining is one that produces highly concentrated effluents from the interaction of water with various types of minerals. These effluents originate from mining processes as well as from rainfall.

-

Wash waters can contribute to mining effluents.

-

Acids Flow Process

-

Leaching, flotation, and concentration of water

-

Refining and gas scrubber effluents

Meanwhile, rain that infiltrates the mine’s tailings can trigger oxidation, hydrolysis, washing, and other processes that result in highly contaminated effluent.

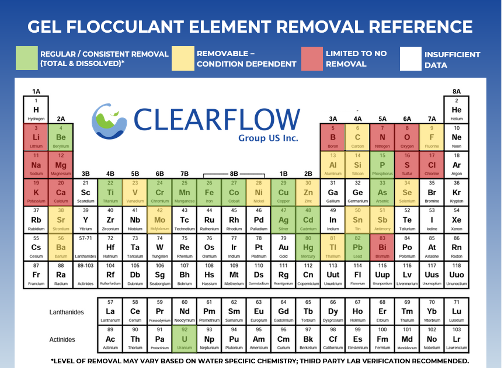

Contact between minerals and water, whether through process or rain, can result in a variety of reactions. The effluents produced vary in composition depending on the nature of each mineral, as there are some that are more or less soluble, hydrolysable and non-hydrolysable, and sorbents and non-sorbents. As a result, the discharge of such wastewater might have catastrophic implications in mining and its environment by entirely changing the chemistry of the water.

Traditionally, these effluents have been treated using physicochemical that are harmful in nature or biological approaches which are not fast – acting. At the moment, Clearflow’s zero discharge environmentally friendly Gel Flocculant products has shown to be the best option. It protects the ecosystem and allows for water reuse in areas where access to water is limited. Furthermore, once installation costs are recovered, zero discharge is the most cost-effective long-term option.

Clearflow Group water treatment products are transforming processes, operations, assets and people – providing secure, standard out-of-the-box solutions for challenges faced across the Mining industry, from the Refining Material to Discharge – helping you set up your operations right from the mining PROCESS TO THE ENVIRONMENT.

Some Features of Clearflow Smart Mines are?

- Maximize existing investments

- Minimize costs to the client by integrating with and utilizing existing infrastructure wherever possible

- Design effective and simple systems, products and processes that can be performed using minimal high-level technical personnel by leveraging Clearflow underlying applications, technology.

Introducing Gel Flocculant Cationic Neutralizer 369

Download Gel Flocculant CN369 Brochure

The Future of Mining is Optimized & Sustainable: Maintain operations sustainability across all stages and ensure maximum productivity and efficiency

Rapidly & Safely Meet Your Mine Water Treatment Needs

Water scarcity, along with legal limits, is altering the landscape of mining site water management. Clearflow Group Inc has spent decades assisting mining industries in meeting existing and future environmental regulations.

Mobile mine GFR water treatment systems can begin generating high-quality water as soon as four hours after arriving on site and have been deployed in a variety of difficult-to-reach and isolated locations.

Clearflow Group US Inc. provides the Mining Industry Assistance with:

-

Rapidly treating excess water for reuse

-

Meeting stringent discharge requirements, including cationic neutralization

-

Allowing for the proper release of water

-

Improving water recovery, including minimal and zero liquid discharge (ZLD) standards

-

Treating tailings pit / pond waters

-

Removing high solids and particulate via membrane filtration

-

Protecting Reverse Osmosis (RO) membranes with pretreatment

-

Becoming less dependent on external water supplies

-

Preventative water channel erosion control treatment

Whether water reuse or wastewater management is your goal, Clearflow offers a variety of solutions designed to meet your needs. Contact us today for more information about our mine water solutions www.clearflowgroup.com/contact-us/.